Finally we were successful in bringing the newly developed software and hardware together for a few days of actual fabrication. The results are extremely promising, showing stone structures that would not be possible through manual methods. On-site collaboration between the programming, stone, and robot experts allowed us to extremely quickly iterate variations, rapidly improving the results.

Incremental Forming

We are again exploring new strategies towards dynamic robotic toolpaths as part of a workshop on incremental forming at Tongji University in Shanghai, China.

New Tool Available

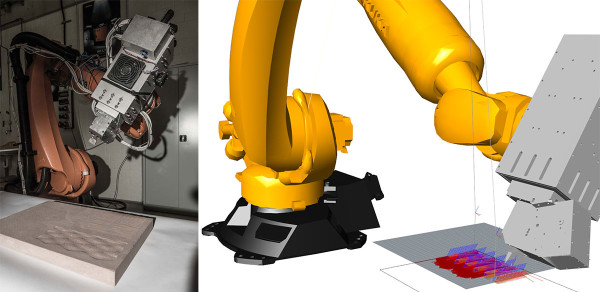

A new iteration of the AROSU tool has been released, much more closely emulating the mason’s movements. On the programming side, new approaches towards raster-based toolpath generation are explored, with the final goal of allowing users to upload media through a Web-To-Real interface and receiving a custom-structured stone surface with that image. Towards that goal we are investigating how to preview the effect of the tool onto the stone.

Parametric Robot Control @ ACADIA 2014

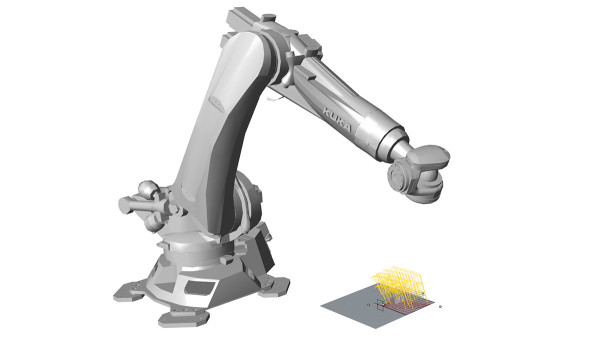

We tested some of the parametric programming strategies that will drive the robotic stone structuring as part of a workshop at USC in Los Angeles, USA. Rather than structuring stone, the international researchers and practitioners work with foam that is hotwire-cut into 3D-shapes.

AROSU Meetings @ Bamberg and Rome

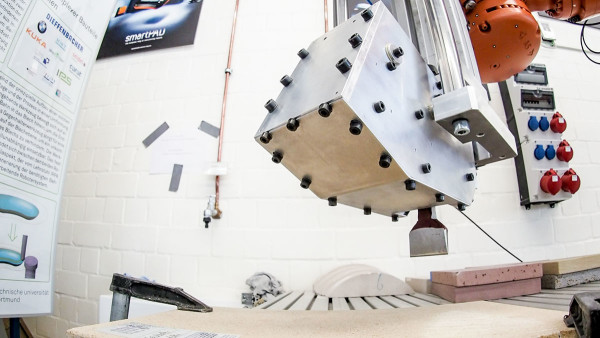

AROSU launched into 2014 with a very intensive workshop session at consortium member Bamberger Natursteinwerke, where they’ve got decades of experience with structuring stone. To accurately analyse the existing, manual processes for structuring stone, the team of TU Dortmund put markers onto the masons’ tools and used two high-speed cameras to capture the movement of the tool in 3D-space. Additionally, a re-purposed force-torque sensor captured the forces that resulted from the individual strokes.

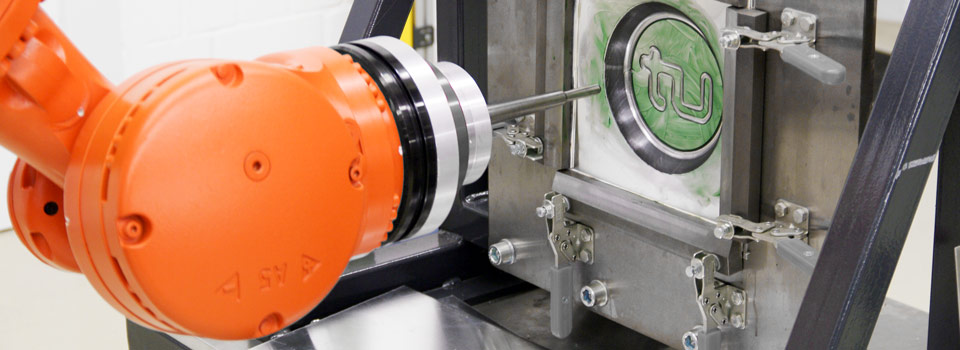

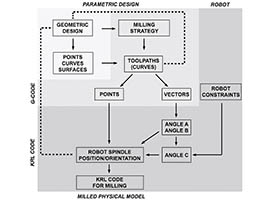

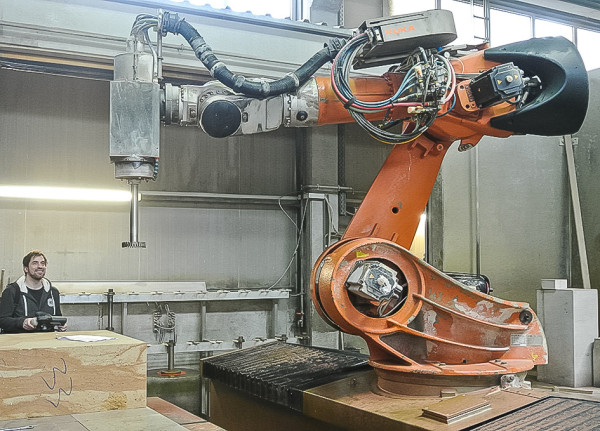

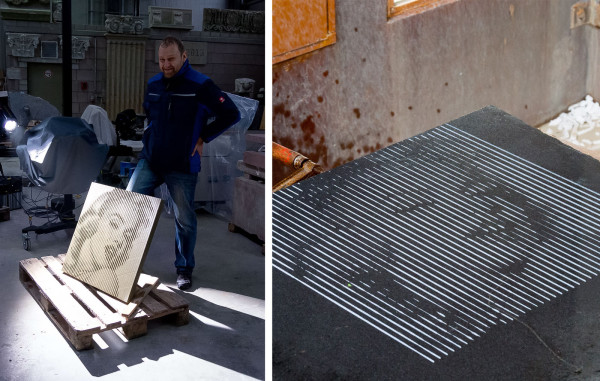

On the robot side of things, the team of the Association for Robots in Architecture verified that the KUKA|prc software environment works well with Bamberger’s heavy duty KR500 robots – machines that are capable of lifting half a ton, or mill through massive stone. As a proof of concept for stone structuring, the researchers experimented with a dynamic robot program that takes data from an image and turns it into code that has the robot cut a complex surface structure into stone – having the photo reappear as a dynamic shadow. In the second example, much harder black, polished granite was cut with a high-end tool in a similar fashion.

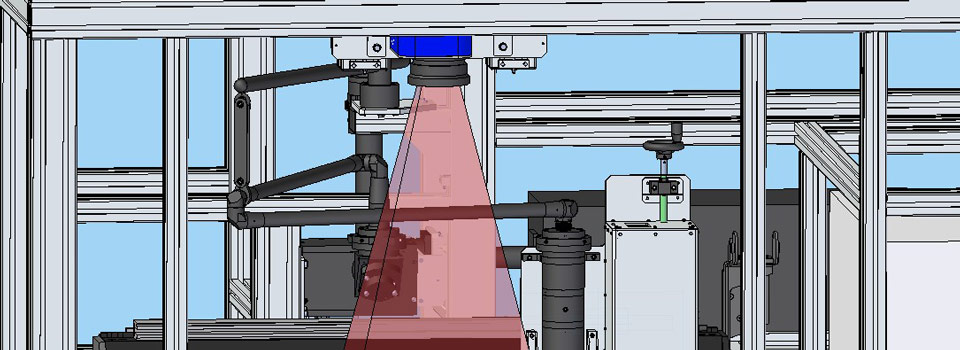

In June, the next meeting took place at Labor in Rome, where one of the focuses was the development of a new, de-coupled stone-structuring tool. With all concepts in place, the development and prototyping is now underway, with progress also incurring in the parametric pathplanning as well as the stone-measuring processes.

In June, the next meeting took place at Labor in Rome, where one of the focuses was the development of a new, de-coupled stone-structuring tool. With all concepts in place, the development and prototyping is now underway, with progress also incurring in the parametric pathplanning as well as the stone-measuring processes.

Shortly after the meeting in Rome, the Association for Robots in Architecture presented initial results of the AROSU project at the “From Stone to Robots” symposium in Firenze, Italy to a wide audience of artists, designers and engineers.

Rob|Arch 2014 – Robotic Fabrication in Architecture, Art, and Design

AROSU attended the second conference on robotic fabrication in architecture, art, and design – Rob|Arch 2014 at the University of Michigan.

AROSU @ TU Dortmund

The Institute of Production Systems at TU Dortmund, one of AROSU’s research institutions, hosted the next AROSU coordination meeting. With the project now in full go, this was not only a grand tour of their workshop, but involved serious discussions and even the first stone prcoessing experiments.

2nd AROSU Meeting in Bamberg

The consortium was meeting up today at AROSU partner Bamberger Natursteinwerk, where Hermann Graser gave us a tour of their workshop and several huge KUKA KR500 robots for stone milling. Just as exciting were the manual and semi-manual stone processing techniques that are used in parallel.